The Melton Forward Control

This is an edited version of an article by Keith Reedman which first appeared in the Derbyshire Archaeological Society’s publication Derbyshire Miscellany in 2009

A noticeable difference exists between the appearance of lorries in Europe and trucks in the USA. In Europe the driver’s cab is usually right at the front and in the USA the driver sits behind the bonnet, which to our eyes seems old fashioned. The general adoption of forward control in Europe owes something to a wholesale greengrocer in Long Eaton.

Not long before the First World War, the Nelson brothers, William and Thomas, came to Long Eaton from Shepshed in Leicestershire and founded a wholesale fruit and vegetable business. Bill Nelson had previously worked for a Loughborough-based merchant and had been making deliveries in the Long Eaton area, so he was familiar with potential customers. Originally the brothers operated from a disused theatre building in Queen Street which had been vacated in 1910 when the new Palace cinema was opened in the Market Place.

In 1914 the brothers built a pair of semi-detached houses in Northcote Street for their own occupation with a range of stables and cart sheds at the rear and an office at the yard entrance. In 1919 they added a large warehouse at the rear which contained a sub-basement for the specific purpose of ripening bananas. Exactly when they moved from horse to motor transport is uncertain but they were using motor lorries during the 1920s. By 1932 they decorated one for the local hospital carnival.

The motor lorries of that time were often supplied by manufacturers with a driver’s cab but without any other bodywork. Coach and body builders would then provide the load platform to order, suitable for the customer’s requirements. Evidently one of Nelson Brothers’ lorries was ill-suited to the job because the load platform was too small. So toward the end of the 1920s they asked Noel Crowe, owner of the local garage business of Wallis & Co Ltd, to extend the platform.

Noel John Crowe (b. 1908) was the son of Emmanuel Crowe, one of a dynasty of Crowes who had all been in the Long Eaton lace industry. The 1920s had seen a dramatic decline in the lace trade and in 1926 when Noel left school at Trent College, Long Eaton, he had no intention of joining his father’s business. Instead he persuaded his father to lend him £900 to buy a garage business from Wilfred Wallis. This business did not have a long history, having been set up by Wilfred Wallis after the death of his father William in 1921. William Wallis had been a partner in the Long Eaton lace machine building firm of Wallis & Longden and Wilfred had been apprenticed to that firm. After his father’s death Wilfred severed the connection, again almost certainly because of the poor state of the lace industry. In 1922 Wilfred submitted plans to the Long Eaton UDC to ‘Erect Motor Garage, Shop, Showroom & Offices … in Derby Road’. Subsequently a substantial workshop building in Oxford Street which had been built in 1906 and which backed on to the Derby Road showroom was used for the business. After selling the motor business to Noel Crowe in 1926, Wilfred Wallis retained the showroom on Derby Road and set up shop as a dealer in wireless sets which were just then becoming the latest trend.

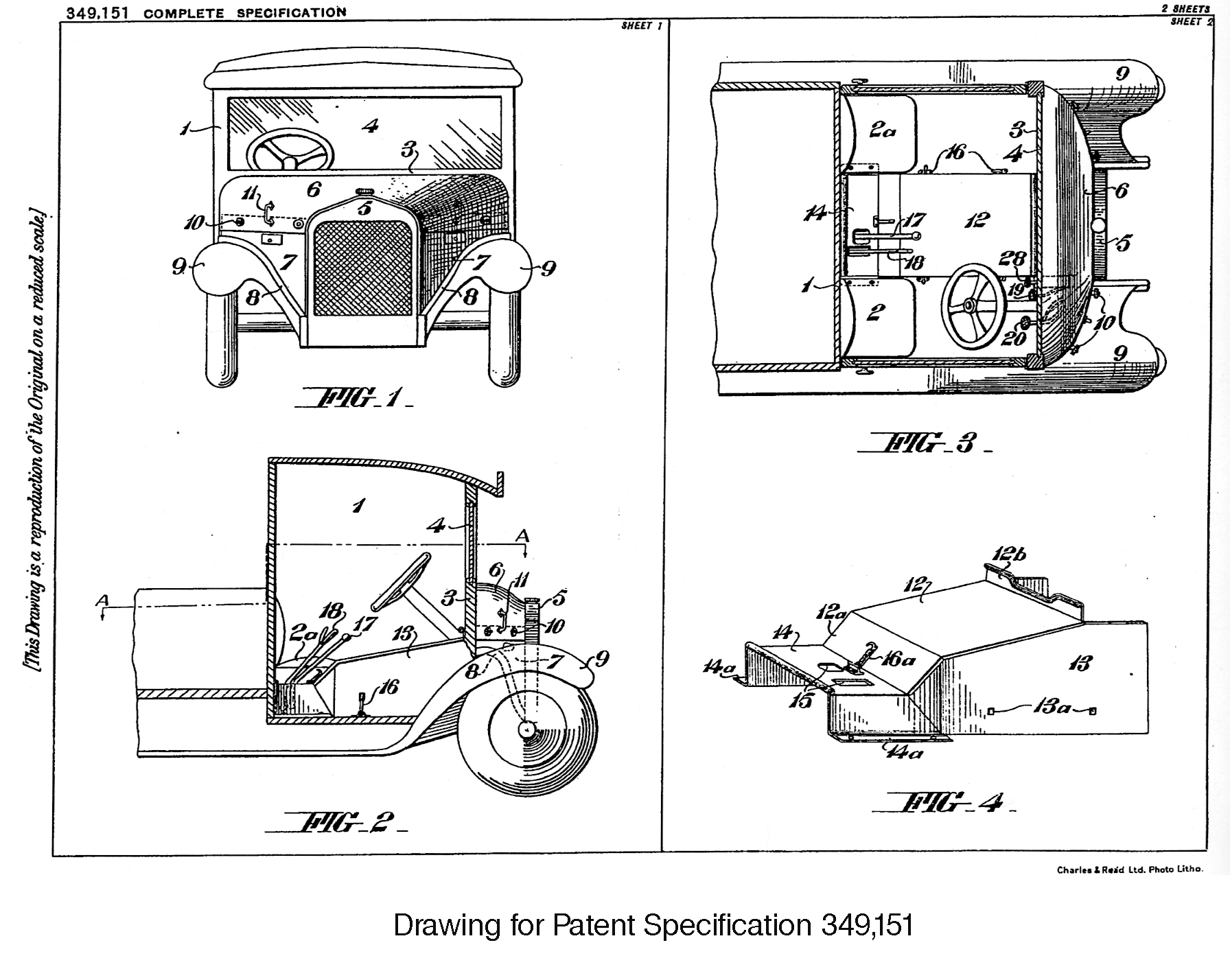

Having acquired the Wallis motor business and incorporating the firm as Wallis & Co Ltd in 1926, Noel Crowe expanded by buying another local garage on the corner of Nottingham Road and Conway Street which had been started in 1907 by Launcelot Harriman, son of another local lace manufacturer. With Crowe having well established himself in the motor trade in Long Eaton it is not surprising that the Nelson brothers should have asked him to modify their lorry. In the event, Crowe decided that extending the load platform of the lorry was not a practical proposition as it would have moved the centre of gravity of the load too far back in relation to the rear wheels, causing instability. However, he had a solution: by re-siting the driver’s cab over and to one side of the engine, the load platform could be increased by the area formerly occupied by the cab. This solution was so satisfactory that on 4 March 1930 Noel Crowe applied to patent his idea. Patent number 349,151 was accepted on 28 May 1931, titled ‘Improvements in or relating to Motor Road Vehicles’

The main patent specification was ‘…to provide an improved construction and arrangement … wherein the carrying capacity is increased by locating the driver’s cab over the engine instead of, as is customary, at the rear of the said engine and to provide a motor vehicle with forwardly arranged driver’s cab … wherein the entire engine is readily accessible without dismantling any part of the vehicle body’.

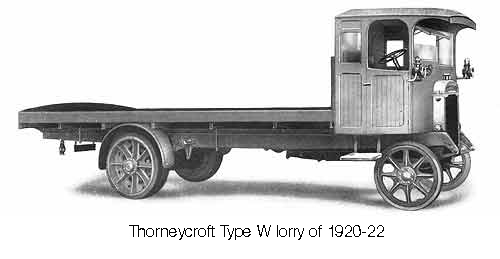

It seems that the Patent Office was generous. The positioning of a driver’s cab right at the front and above the engine in a road vehicle was not novel. Thorneycroft of Basingstoke had a steam wagon thus arranged before 1900 and by 1922, their type W petrol engined lorry had forward control.

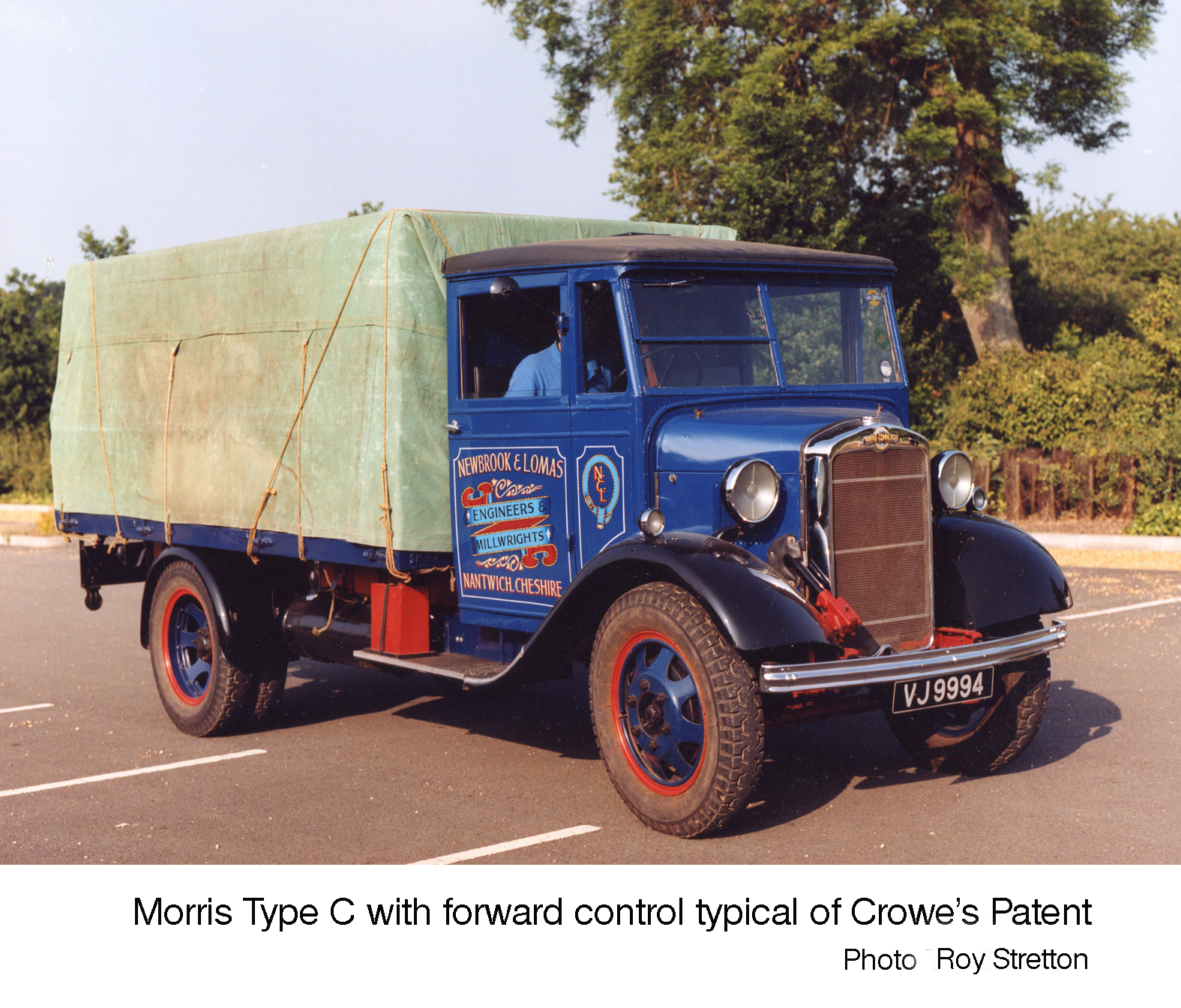

On the continent both Panhard & Levassor in France and Benz in Germany had similar arrangements before the First World War. Even in the USA a forward control was built on a truck before 1920 but it never caught on there. By the time of Crowe’s patent in 1930, forward control was well established in Britain but only a small proportion of lorries were built in this configuration and of those, most were the heavy load types. Some manufacturers offered the same vehicle with both layouts. It seems that although Crowe’s patent was used to convert existing vehicles, it was mainly employed by manufacturers to convert their existing conventionally designed lorries to forward control.

Noel Crowe named his idea the Melton Forward Control, taking the name Melton from his house on Derby Road, Risley. The term commonly used was ‘Forward Control’ and the idea of the conversion was quickly taken up by many motor manufacturers including Ford, Morris, Dodge, Commer, Reo, Studebaker & General Motors (Bedford). To cope with the conversions he was asked to carry out, Crowe expanded his garage site southwards in Conway Street. Such was the demand that he installed a 125 ton mechanical press to produce cab parts for Morris Commercial vehicles and opened a depot in Burnt Oak, Edgware to deal with work for both Ford at Dagenham and General Motors at Hyde in Middlesex.

Quite quickly during the 1930s most manufacturers incorporated Forward Control into their basic design and Crowe began to accept a royalty payment rather than to manufacture components for conversions. For instance, the lorry manufacturer ERF, founded in 1933, adopted forward control in its first designs. So although Crowe continued to be make bodywork pressings for some years he could see that the motor manufacturers would not continue to rely on his limited production and sought an alternative product. By 1933 it had been decided to use the capacity of the large mechanical presses to manufacture stainless steel sinks and the trade name of ‘Leizure’ (later changed to Leisure) was adopted.

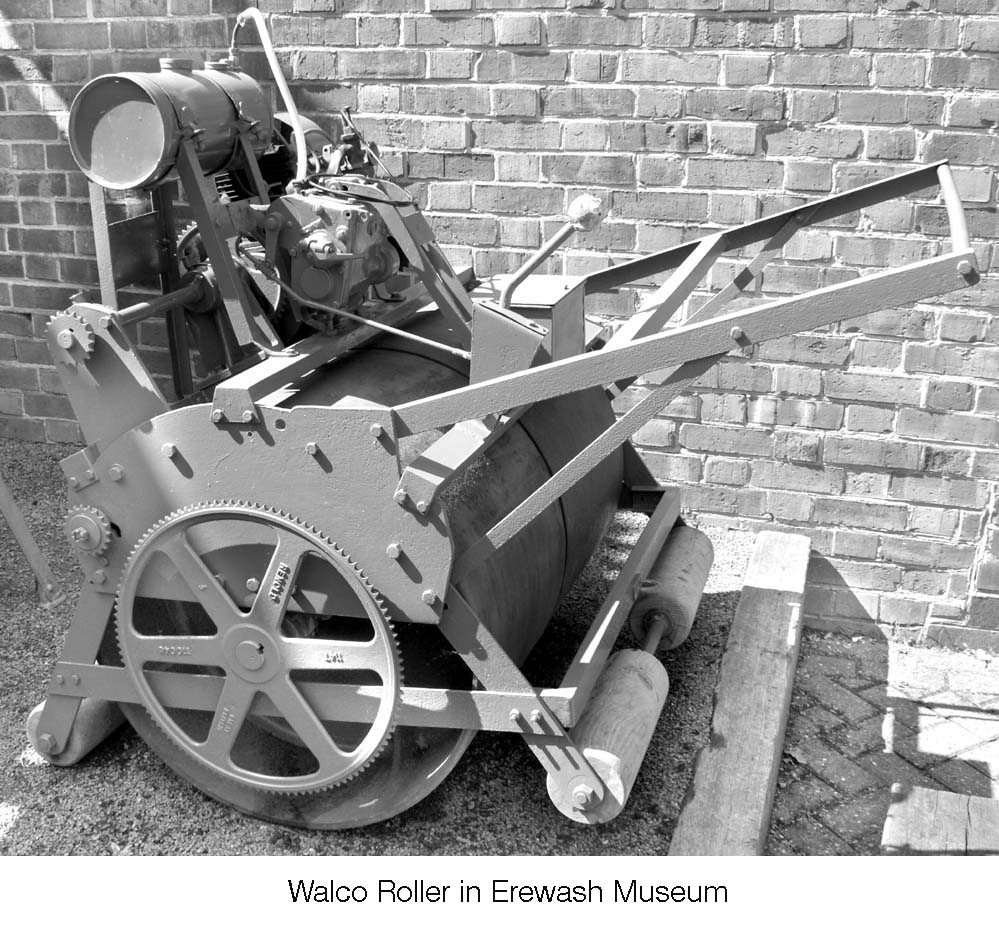

Stainless steel sinks had been an American idea and it seems ironical that the forward control had been quickly adopted on this side of the Atlantic by American vehicle manufacturers without it becoming standard in their homeland. The stainless steel sinks which were produced in quantity by 1935 were new to the British market but were very expensive and by 1937 cheaper vitreous enamelled pressed steel sinks were manufactured. Crowe also manufactured, for a short period before WW2, ‘Walco’ hand operated motor rollers, an example of which is preserved in Erewash Borough Museum at Ilkeston. When the site on Conway Street became too small the company expanded to a large site on Nottingham Road to the east of the High Level railway line.

In 1954 Noel Crowe sold the business to Allied Ironfounders for the then large sum of £750,000. The business which has now evolved into Leisure Consumer Products, part of the Aga Rangemaster Group, still manufactures Leisure stainless steel sinks in Long Eaton at a large factory which was purpose-built in Meadow Lane in 1956-8. The garage business which was separated in the 1950s still operates on Nottingham Road under the badge of Kwik-Fit but the 1907 Conway Street garage was replaced by a block of flats in 2005. Wallis’s garage in Oxford Street, formerly ATS, is vacant and the former showroom at 37 Derby Road, which after the Second World War became a television shop, is now Ellis-Femor & Negus, solicitors.

Following the death of the original Nelson brothers the firm continued to operate within the family. William’s children Gerald and Jessie and Thomas’s children Jack and Arthur carried on until the business was sold shortly before Gerald Nelson, the youngest, retired in 1987. The houses and warehouse were demolished for redevelopment in 2009 and the firm is no longer trading.

Acknowledgements

I am grateful to Mr Ralph Brown formerly of the Leisure Company for initially bringing the Melton Forward Control to my attention. My thanks also to Mr Mike Bufton of Aga Rangemaster for allowing me to use information from an unpublished company history. Mrs Miriam Nelson has supplied valuable information and I am also grateful for the help and advice given by Margaret Alsopp, Caroline Marshall, Gerald Newbrook, Norman Painting and Brian Waters.